To properly read this post, go mix yourself a cocktail and drink every time you read the word “screw.” Also you should probably smirk every time you read the word too, since, you know, we have the sense of humor of 12 year old boys over here. Got your drink handy? Okay, let’s get into this.

Once the insulation was in I started trying to find a good friend to help me install the drywall in the bathroom. I knew there was absolutely no way whatsoever I could do the full install alone. Lucky me, eventually a friend casually mentioned he worked a summer installing drywall in college. Bingo! He had no idea what he’d just gotten into with that comment. I immediately started talking about my upcoming project and dropping hints. With the floors now covered in HardieBacker It was time to whip the walls in shape. I just had to wait for the plumbing inspection to finish so I could drain the drywall pan!

Luckily, I soon passed inspection and after dropping too many hints, went ahead and asked my friend Janik to come help me drywall. Before that could happen I was faced with the dilemma of how to actually get the drywall… because 4’x8′ sheets weren’t going to fit into my VW Tiguan! As usual, I was discussed this issue with my neighbor Erik. And because he is an angel child, the man volunteered to meet me at Home Depot with his truck the next Saturday to buy drywall. He had to go anyways to pick up a few things. At this point we were each going to Home Depot 3-4 times per week and we were picking up things for each other on 1/4 of those visits. You guys, my inbox of electronic receipts from Home Depot is over 200 messages. In just over 1 year!

Anyways, I drove to Home Depot that Saturday and looked at drywall stuff. Erik met me there and convinced me to buy a bunch of drywalling stuff and then told me the drywall was cheaper at Lowe’s. We got into our respective vehicles and drove 10 minutes to Lowe’s. But when we were there, they only had normal 1/2″ mold resistant green drywall board. HomeDepot carried the ultra-light version of the same product. So back in our cars we went and back at Home Depot I purchased the sheets and tools which we then slid into the back of Erik’s truck. At my house, Erik helped unload the sheets of drywall into my kitchen storage room where I was staging everything for the bathroom remodel. I was glad we went back for the ultra-light drywall at that point considering how dang heavy the ultralight version was!

Janik was coming over the next weekend, so I was able to fully assess my supplies and read up on the tutorials on hanging and mudding drywall on younghouselove.com. I gathered everything I had purchased and double checked I had everything I needed a couple of times.

- 6 sheets mold resistant ultra-light drywall sheets at about $15 each

- 1 box drywall screws

- 1 roll paper drywall tape

- 2 metal strips of outside corners at $3 bucks each

- 1 drywall pan at $5

- 1 corner tool for $10

- 1 each 6″, 8″, 10″, and 12″ drywall knives at $10 each

- 1 four gallon bucket pre-mixed drywall compound $15

- 1 drywall cutting edge $15

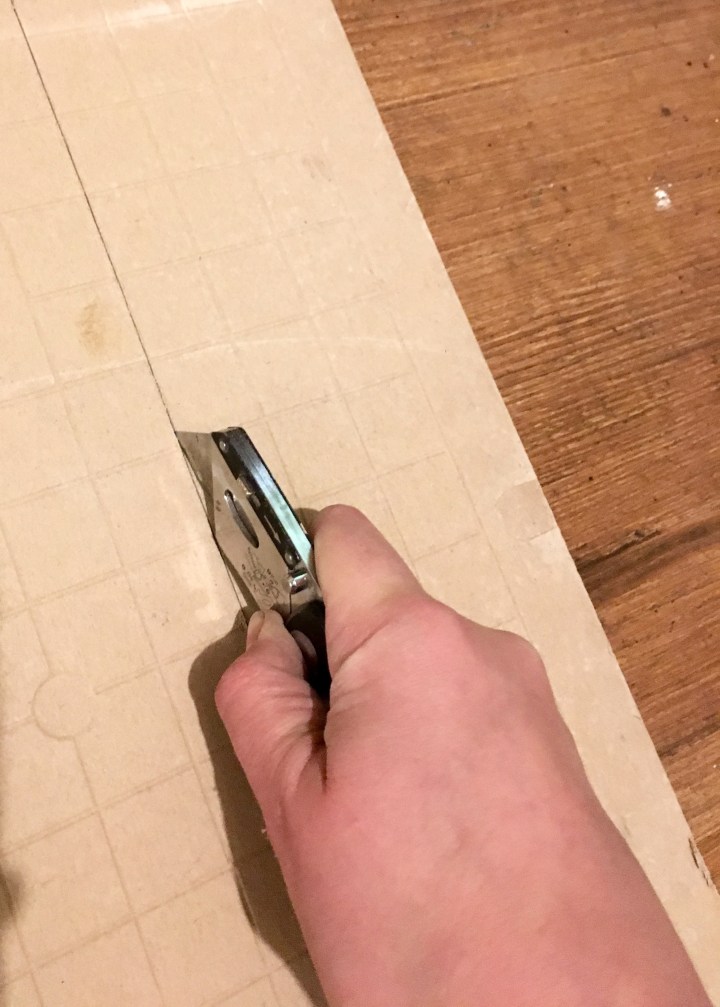

- 1 box cutter knife

- 1 tape measure

- 1 jagged edge drywall knife

- 1 billion (or about 6ish) drywall sanding blocks

I started with the easiest piece of drywall on my own: the lower part of the exterior wall, just to see how quickly this could go. After I measured the wall a couple times, I scored the paper outside of the drywall with my boxcutter and snapped it neatly along that line. I cut a second piece to fit around the window frame and then shoved the whole thing against the wall and screwed in drywall screws every 16″ with my handy new impact driver. The whole piece took 20 minutes tops, so I figured the whole room would go very quickly. Ha!

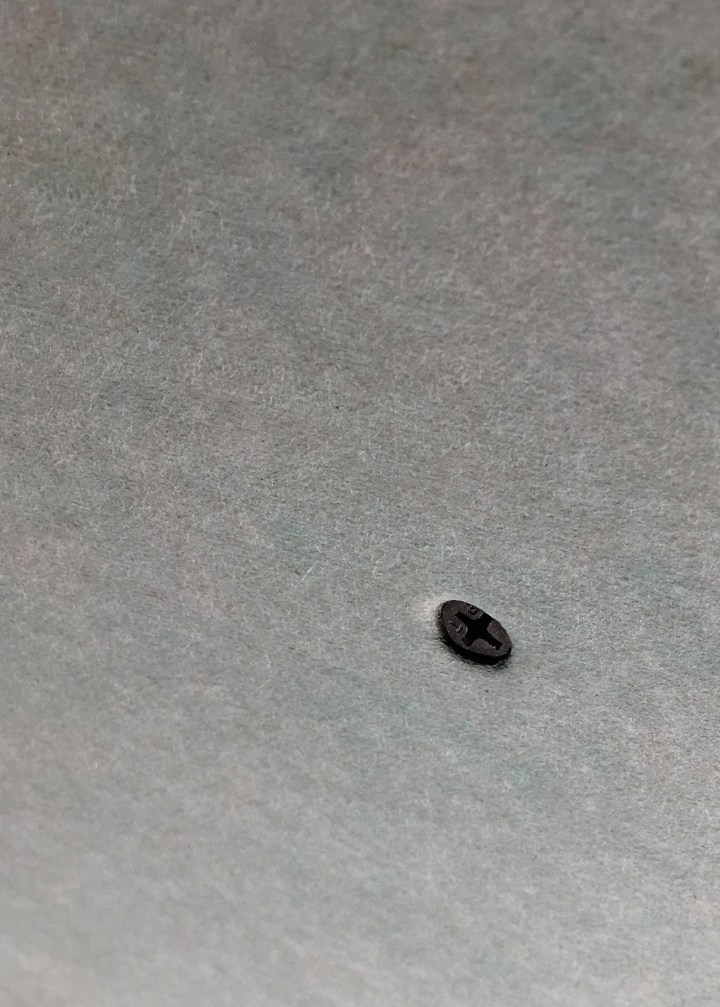

Now they make special drill bits for hanging drywall that prevent you from screwing through the paper and I eventually tried them, but I didn’t care for them as they prevented me from seeing and feeling the screw go in. It’s important to sink the screws just enough to recess their heads, but not enough to break through the paper. Here’s an example of a perfectly sunken screw.

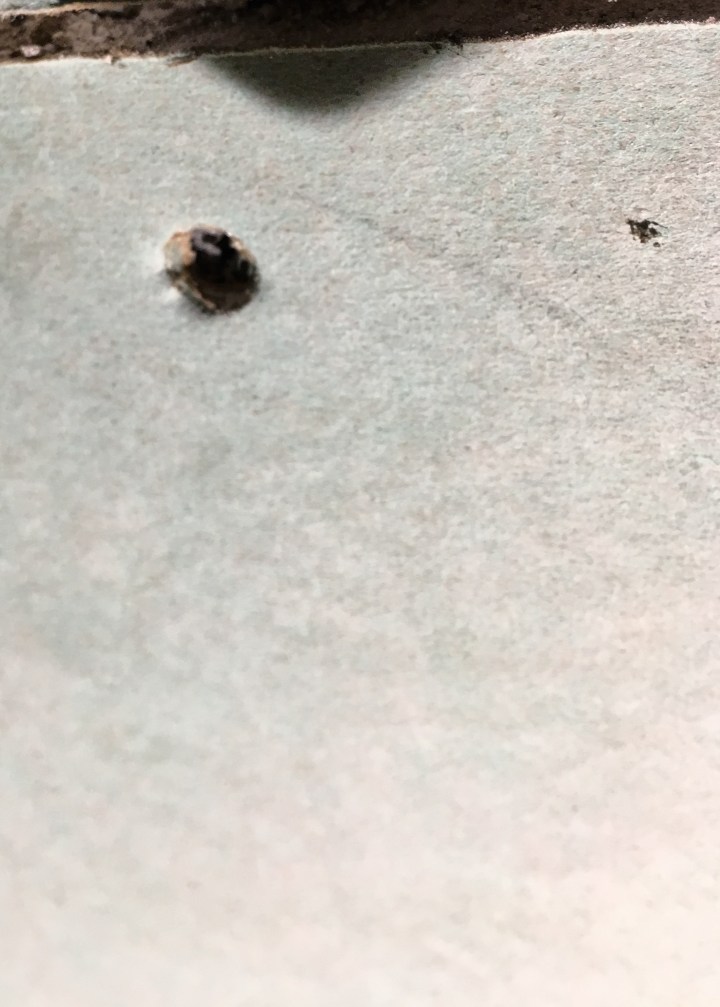

Because the strength of drywall really comes from the paper, it’s super easy to cut (much easier than the hardiebacker!) and once the paper is cut the rest snaps very easily. This means screwing in the boards is a bit sensitive, since if you break through the paper, your screw is no longer holding on to anything at all. Here’s where my screw went in a little too far, you can see the rough edges. It’s a delicate balance of trying to get the screw to sink juuuust right. But once you get the hang of it, screwing into the drywall is pretty easy and if you mess up, you just sink another screw near the first. No big deal.

Later that week Janik arrived at my house ready to help hang the rest of the drywall. We got right to work templating the places to cut holes into the drywall sheets on the opposite side of the room. I took some primer that was nearby and dabbed it all over the edge of the sconce electrical box edge. Then we simply cut our sheet to the correct length and pressed it against the wall and electrical box. The primer left a nice circle on the sheet and I cut that out with a jagged edge drywall knife and gave the sheet a tight fit around the box.

Piece after piece the walls came together and the bathroom became room-like again! It worked well to have two people on this job as one person could hold the sheets and the other person could screw. That sounds dirty, but you know what I mean! We made a good team since Janik is much more of a precision type person and I am a “well, it’s good enough” kinda person so the drywall job ended up right in the happy middle of those two as we worked efficiently around the room. I was particularly grateful for a second person when we started the ceiling since our arms were both screaming waiting for the other person to finish screwing in the sheets above our heads.

I had Janik wear an extra pair of crocs that were lying around Berrybrier since crocs are the shoe of choice for this renovation. I’m sure he appreciates this being memorialized on the internet.

The ceiling was absolutely the hardest part since this is an old house and nothing is perfectly square. Holding a sheet of drywall up above your head while another person tries to figure out what needs to be cut an an angle in order to make it all fit is exhausting and really a great arm work out. But I hate arm work outs, so I was all for cutting a bit deeper and mudding a bit more.

We diligently worked around the room and ceiling cutting out for the plumbing pipes and medicine cabinet with the same technique we’d perfected with the electrical box, though we some how messed up on at least one plumbing pipe hole and made an extra hole. Otherwise, we just cracked joke after joke about screws and time passed pretty quickly. All of a sudden it was 2am, 8 hours after we started and we finished screwing in the final piece of drywall in the ceiling and paused to get water in the kitchen. As soon as we stopped my body rebelled and I was ready to collapse with exhaustion. But the bathroom had walls again!!!

I took a few days to let my arms recover from the first real arm workout I’d done in 5 years. But there’s no real rest for the weary round here. It was time for some mudding, the hard and dirty part of drywalling. I was not looking forward to it. But I psyched myself up with chai lattes and the promise of actually being able to shower. That tends to work for me!

First I taped down rosin paper to protect the floors from stray drywall compound. Then, I started out by filling every single one of the ten billion screw holes with a bit of drywall compound, before moving on to the more challenging parts. I continued with the next baby step: the seams along the middle of the walls. I spread a thin layer of joint compound in the seam with my 6″ knifeand laid the paper tape on top, then gently pressed it into the seam with a tad bit more mud. I spread slightly more mud over the tape working with the 8″ knife. After this first coat those seams looked pretty rough, as expected.

I moved from there to the outside corners framing the shower surround. I cut the outside corner metal strips to length and screwed them into the drywall, working from the top down. You can get rounded corner or 90° angle metal strips, I chose the former since they were better suited for this style house.

Once it was screwed on, I globbed on a whole bunch of the drywall compound with my 6″ knife. It was a challenge to smooth the mud on one side of the tape without shoving the excess mud onto the other side of the corner. I did my best and moved on to the inside corner seams around the room, folding my paper tape into a 90″ angle and working it into the seam as I had on the flat seams.

I used SO MUCH mud for the first coat. I worried I’d run out of my 4 gallon bucket of joint compound before finishing this small room. It was later November at this point and it was cold! I still had not turned on the heater in the house and was sleeping at my cousin Kristen’s after working on my house all evening, every evening. Because the house was so cold, the thick first layer of mud took several days to dry and cracked a bit in the inside corners. Since it was the first coat, it wasn’t a big deal that it had cracked, but I knew I needed to get that furnace tuned up and running asap!

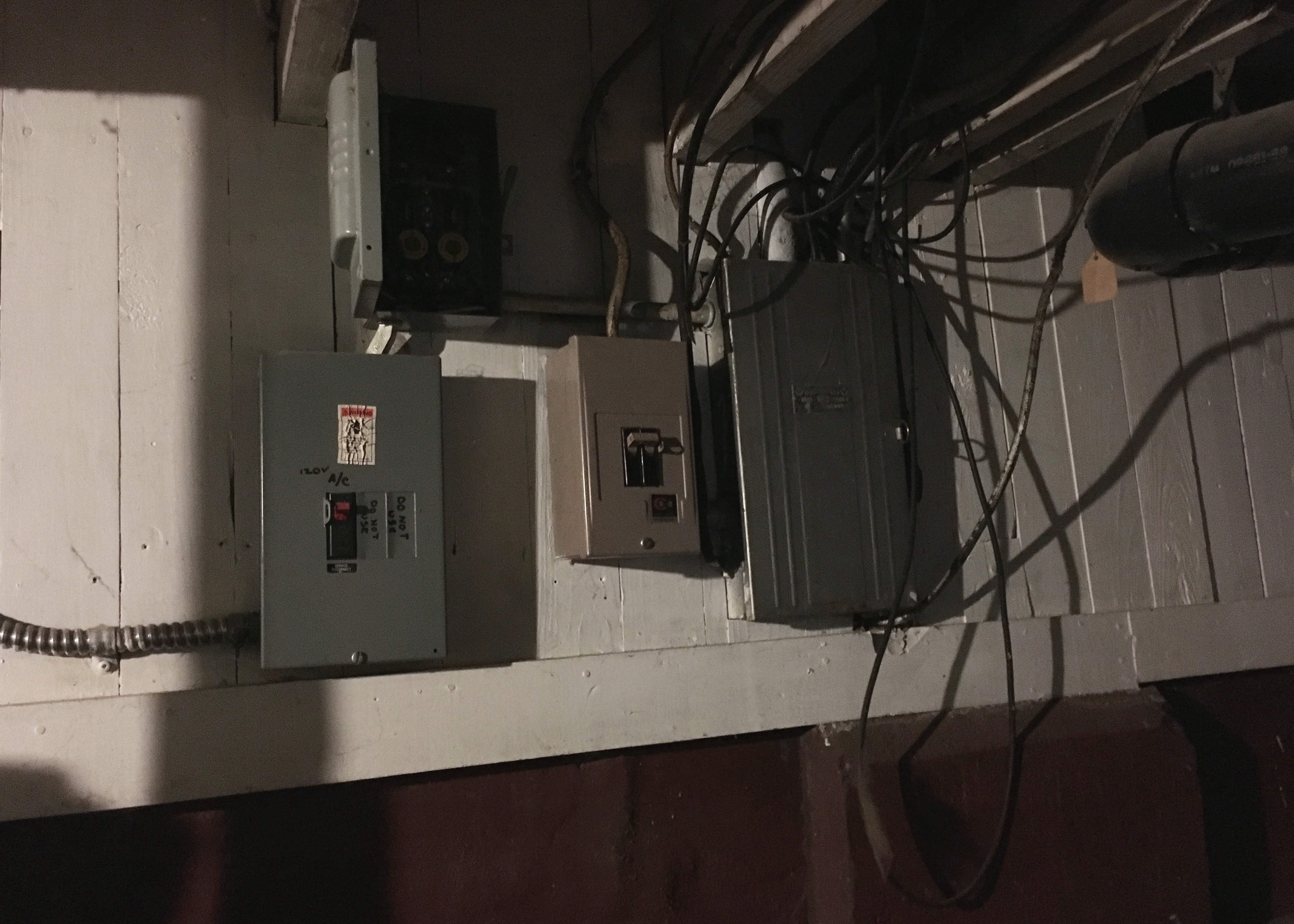

I had the HVAC guys come out the day after Thanksgiving to fill up my tank with oil and give the 1920s furnace a good tune-up. Once that was cranking, the house stayed a tad bit warmer and the drywall compound dried a bit more quickly on the next coats.

I knocked off the higher bits and lines with a 6″ knife before starting the second coat of drywall mud and then used my corner, 8″, 10″ and 12″ knives to spread out the mud from the corners and seams as thin as I could. After that dried for a couple days I did my third coat, creating a heavy layer of mud, that was probably more than is recommended, but worked out just fine. Here’s that same outside corner by the shower surround after the second coat of mud. The last coat went on the smoothest and I thinned the mud slightly with some water in a second bucket to allow for a thinner coat.

Then it was time for sanding. SO MUCH SANDING. I sanded this room for weeks, ya’ll. I was sanding still in mid-December. Sanding and sanding and sanding. I used the sanding blocks and then borrowed a sanding screen from Erik which worked more quickly, but left more of a linear pattern than the sanding blocks. Drywall dust was in my pores and my skin was dry dry dry, but the room was looking more and more room-like and this corner was looking ready for primer.

The walls got really smooth and the edges of the outside corners felt really good too. The ceiling was much more difficult and I honestly, just decided after a couple hours of sanding, it was plenty good enough, because I wasn’t sanding above my head any longer. See comment above about my “eh, it’s good enough” attitude.

Eventually, after I don’t even know how many hours of sanding, the bathroom was smooth as a baby’s bottom and ready for primer and paint! At last! My showerhead had been installed and as soon as the room was primed, I could shower again. Boy was I looking forward to living in my own house again. My 10:30pm 15minute sprints back to my cousin’s to shower and sleep were getting old quickly. I needed to be staying at Berrybrier full time to get through the push! But here we were with a bathroom with ACTUAL WALLS AGAIN!

Already this room was looking one million times better than where it had started and even with the drywall dust, I was happier to walk in here now than before! Now the room was taking shape and the new layout was feeling real for the first time. Boy did it look more comfortable than sneaking around the sink and gross tub to get to the toilet!

Great progress had been made and I was so freaking excited for the next steps: paint and tile! Have you ever drywalled a space before? Was the ceiling the worst part for you too? Did you think you were going to be sanding forever? Would you ever do it again? Commiserate with me in the comments!